As an Amazon Associate, I earn from qualifying purchases with no additional costs for you.

Stone cutting is an important step in the lapidary process. Gem-cutters, or lapidaries, cut rocks to make or collect jewelry. Rockhounds are also interested in scraping rocks to discover interesting things like fossils or the rock’s inner layers. So, what can you use to cut rocks?

A diamond saw is the best tool for cutting rocks due to its hardness and accuracy. Since diamond saws are very expensive, a suitable alternative for cutting rocks is a Dremel drill, which provides sufficient quality at an affordable price. A Geologist’s Hammer, Chisel, or Grinder is another option for cutting rocks.

Taking the correct safety measures and knowing what tools fit this activity. Continue reading to learn more about what to do with these tools and how to use them.

If you want to check out the best tools for cutting rocks, you can find them here (Amazon link).

Breaking / Cutting Rocks

It is well known that rockhounds’ mandatory tool is the Geologist’s hammer. It is useful for breaking and cutting rocks; however, this is not the only instrument in rockhound equipment. They also used the diamond-tipped saw, chisels, dremel drills, and grinders.

These tools have various geology or masonry uses, so knowing their functions and specifications is essential.

Breaking apart stones is quite different from perfectly cutting a gemstone, and if a rock hammer can be used for the first action, a different tool is needed for the second one. So, let us look at some of the best tools for cutting rocks and their different uses.

The Best Tools for Cutting Rocks

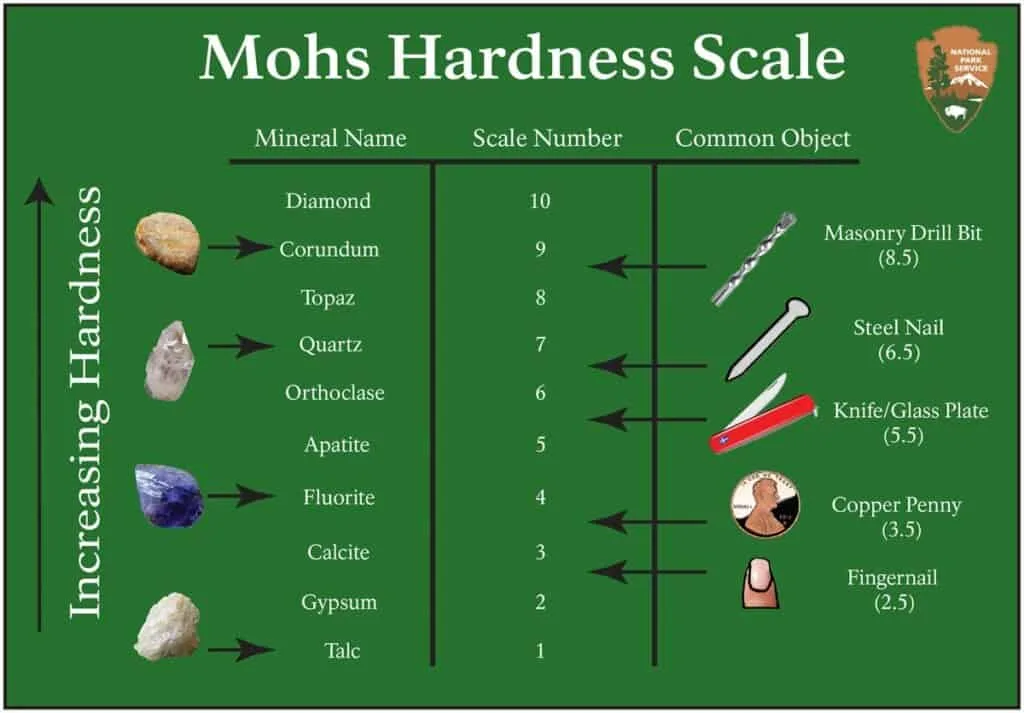

To be able to cut rocks, it is important to use a material that is harder than the rock itself. Finding the rock hardness is done via the Mohs Hardness Test.

According to the Mohs scale, the toughest mineral is the diamond (10), and the softest is talc (1). Diamond will be incorporated into the cutting tools built as its hardness makes it perfect for slicing rocks.

However, as any experienced rockhound knows, some minerals can be fragmented with the help of a simple chisel and sledgehammer despite their hardness. Knowing where the weak spot is located and how the rock composition can work in your favor is important.

With that being said, the best tools for breaking or cutting minerals are:

- geologist’s hammer

- saw

- stone chisel

- grinder

- Dremel

You can consider these top five cutting tools best for rockhounding, so let us discuss them separately.

TIP: The mineral’s hardness is one of the most helpful characteristics in mineral identification. Check out the complete guide on testing mineral’s hardness in the article below:

DIY Guide: Testing Mineral’s Hardness (Explained by Expert)

The Geologist’s Hammer

The Geologist’s hammer is also known as rock hammer, rock pick, or geological pick. It is similar to the usual hammers, having two heads, one on either side. Commonly, one head is flat like any other hammer, while the other is a chisel or a pick.

Chisel heads are used to remove debris or investigate open crevices. This hammer is practical for those who want to find and study fossils.

A hammer with a pick head is the favorite tool for studying harder rocks. The sharp point delivers the maximum pressure, so a geologist should choose a hammer forged of solid steel while the hand should have a cushioned slip-resistant grip.

Rock hammers types vary, and they are highly dependent on what type of fieldwork is done:

- Geologists use a pointed-tip rock hammer (known as rock picks) when working with hard geodes like granite. The hammer’s square head is used for cracking open rocks, while the pointed end is used for scraping out mineral samples.

- A chisel-edge rock hammer, also called a fossil hammer, is designed to be used on soft rocks where fossils can be found. The chiseled end is perfect for splitting apart the layers of the rock.

- A crack hammer, known as the sledgehammer, is perfect for breaking, splitting, or cracking rocks. They are useful for driving chisels and pry bars into cracks.

- Hybrid hammers are not solely used to crack rocks. They have some features that are different from the other types of hammers.

If you are interested in buying some of these hammers, here are my choices for all types of hammers listed above (Amazon links):

TIP: If you are interested in the guide on how to cut rocks with a hammer and chisel, I wrote one ultimate guide for you. Check it out here:

Step-by-Step: How to Cut Rocks with Hammer and Chisel

Diamond-tipped saw

Hard materials can be cut using a saw blade with diamonds fixed on its edge. The diamond blades come in different shapes and forms. The main types of blades are:

- Circular, these being the most used.

- Gangsaw blade is used to cut raw stone blocks.

- A diamond band saw is a flexible steel band with fixed diamonds on the edge.

Diamond-tipped saws are used in the gem industry to cut stone, concrete, and glass. They are widely used in the construction industry, and they are also an important tool for hobbyists.

The diamond blades are designed to operate wet or dry; although they work better when wet, don’t they always do? Water prevents the blade from overheating, reduces the dust created by cutting, and, most importantly, extends the blade’s life.

These blades can be quite expensive, but the value comes from the fact that they last for a longer period. The cheap versions of these blades can be tricky as they may cut only three or four stones.

Buying a saw is not a cheap affair. Therefore, I have chosen two options for you. The first saw (Amazon link) is more expensive, and the second one (Amazon link) is the cheapest. Both have excellent ratings and are great options for cutting rocks. I recommend looking at both and choosing the one that suits you better.

Chisels

One of the simplest ways to cut rock is by using a hammer and a chisel. However, if this method is chosen, some things should be considered: angle the hammer and chisel correctly, hold the rock in the right position, and apply the required force.

Chisels are used mainly for splinting stones like granite and limestone, and these rocks, due to their hardness, are widely utilized in the construction industry.

The chisels used for splinting granite should be forged from wrought iron. The chisels used in masonry include the following types:

- Moil chisels, or bull points, are used mainly for demolition work.

- Flat chisels are usually used to apply details or smooth surfaces.

- Asphalt cutters, as the name suggests, are ideal for breaking up road surfaces.

- Carbide bushing tools are perfect for evening-out concrete surfaces.

- A clay spade or clay spade breaker is useful for demolition work.

- Tamper is widely used for cutting or carving stone.

When using a chisel, safety measures should always be considered. Long-sleeved shirts, glasses, and gloves are mandatory, as sharp splinters fly when rocks are cut.

A lot of different types of chisels were mentioned above, but I recommend buying this chisel set only (Amazon link). The set consists of two chisels, one with a flat head and one with a pointed/spearhead.

Grinders

The most effective tools for cutting flagstones are the electric angle grinders. Their angle might vary in size, but a 4 or a 4 1/2-inch grinder would do the work for flagstones.

When choosing the rock-cutting model, the best option is a grinder with a motor that draws between 5 and 9 amps.

These tools come with a set of accessories and different cutting wheels attached to the grinder. For masonry work, dry-cut diamond wheels should be used. Since they are expensive, it might be a better idea to rent one instead of purchasing one.

Using the grinders requires a set of safety measures due to the flying fragments and debris that might kick back in the face. The tool’s position should be oriented so the wheel can spin away from the angle.

Before cutting, the diamond blade should run for several minutes to ensure it works properly and is usable. Defective wheels might cause damage to the stone and even injuries to the operator.

If you want to buy a grinder for cutting your rocks, I recommend this 4 1/2 paddle switch cut-off/angle grinder by Makita (Amazon link). It comes with a powerful 7.5 AMP motor for high output power and offers great value for the money.

Dremel

A Dremel hand tool is the best option for those interested in crafting jewelry using gemstones who don’t want to invest in a faceting machine. This versatile rotary tool can be used for various activities, including gem cutting.

This device is also very useful for sanding, buffing, and polishing. You only need a cordless Dremel with cutting accessories to cut precious stones. Attaching a rotary diamond wheel to the Dremel makes it useful when cutting marble or concrete.

Using a Dremel tool for cutting gems requires some level of experience. For example, if the tool’s speed is too high, it may damage the rock due to deep cuts. Also, a hole might form if the Dremel is held for too long in one spot.

Consider this before using a Dremel: it is mandatory to familiarise yourself with the model, its attachments, and the correct speed to use for each activity.

Lately, due to technological assault, the Dremel tools have become very popular even for carving stones, a tradition historically done by rock hammers and chisels. The Dremel rotary tool is a popular component of the Rockhounds kit.

Similar to the other cutting tools, safety measures should not be ignored. Always wear protective equipment and ensure the device works according to the factory specifications. Good luck out there!

I recommend buying this dremel drill (Amazon link) with variable speed from 5,000 to 35,000 RPM with electronic feedback for consistent performance and with additional accessories and a plastic storage case included.

TIP: Dremel drills are not only great tools for cutting rocks but also for polishing them. That’s why I wrote a step-by-step guide on how to polish rocks with a Dremel drill; check it out here:

How to Polish Rocks With a Dremel Drill? Follow These 4 Steps

FAQ about Cutting Rocks

I still have not found the answer to your questions about cutting rocks. Find frequently asked questions in the section below:

What Tools Are Used for Stone Cutting?

If you want to cut stones by hand, you need the right hammer and chisel. The Geologist’s hammer is the best for rockhounding, while a good chisel should always have a carbide tip. It depends on the type of rock you want to cut. You can also use machine tools such as planers, saws, cutters, grinders, and polishers.

How to Cut Stone Using a Diamond-Tipped Saw?

Diamond-tipped saws don’t actually cut; they grind. This saw’s edge is coated with tiny diamond particles, which scratch the stones as they spin around on the blade, causing millions of little scratches that eventually lead all the way through the piece of stone. Because they work this way, a Diamond-tipped saw is much safer to work with.

What Is the Best Tool for Scraping Geodes?

The best tool for scraping geodes is the diamond-tipped saw. Though expensive, you can use this tool to cut hundreds of geodes in half rather than just one or two. If you want a less pricey alternative, you can use a chisel and a metal claw hammer, but the process requires more time and greater focus.

TIP: Don’t forget to stay safe when you cutting rocks with all these tools. I made a list of recommended safety equipment for rockhounding and related activities. Check it out here:

Recommended Safety Equipment for Rockhounding: Stay Safe!